- Tel : +86-0311-85236281

- E-mail : sales@wirecloths.com

Title: Double and Half Layer Polyester Forming Fabrics

Key words: Paper Machine Plain Fabric

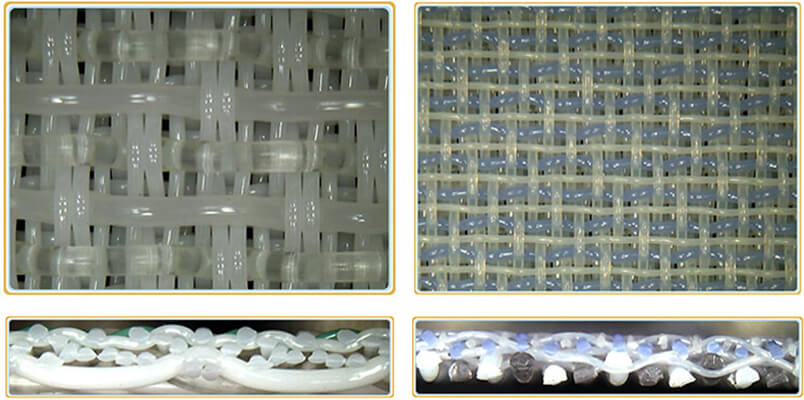

To improve the Double layer design, companies may also consider the 2.5 Layer Forming Fabric. This fabric type is an improved version of the double layer design where the weft density of the sheet side is increased. As the weft increases, the paper’s surface properties improve as well as retention and wire mark. There are different shed layer however the 8-shed and the 16-shed has the greatest potentials.

4-shed single layer polyester fabric is suitable for making culture paper, printing and packing papers etc;

5-shed single layer polyester fabric is suitable for making sanitary, culture and packing papers etc;

8-shed single layer polyester fabric is suitable for making high basic weight corrugated and packing papers etc;

7-shed double layer polyester fabric is suitable for making of high grade print paper and tissue papers;

8-shed double layer polyester fabric is suitable for making high grade print paper, offset print paper,tissue paper and board paper's surface paper,innner paper, etc;

16-shed double and a half layer fabric is suitable for making quality printing paper, tissue paper and surface paper, inner paper and base paper of the board paper, etc;

Multi-shed three-layer polyester fabric is suitable for making quality printing paper, tissue paper and cigarette paper, etc.

§ Newsprint

§ Offset printing paper

§ Cigarette paper

§ Toilet paper

§ Copperplate paper

The 2.5 layer also has higher fabric support and longer life span due to the increase in the water yarn diameter and the long CD crimp. This fabric would best work for medium up to high-speed paper machine.

| Weaving seriesAnd types | Net ID | Filament diameter mm | Density/root cm | Tensile strength | Thickness mm | m³/m²h | Force elongation (in 50N/cmTension Tensile rate not more than) | ||||||

| warp | weft | warp | weft | surface | joint | ||||||||

| 4 heddle monolayer forming net | 27254 | 0.2 | 0.25 | 30 | 22 | ≥600 | ≥400 | 0.49 | 8000 | 0.60% | |||

| 27274 | 0.2 | 0.27 | 30 | 21.5 | ≥600 | ≥400 | 0.51 | 7800 | 0.60% | ||||

| 31204 | 0.18 | 0.20 | 35 | 28 | ≥600 | ≥380 | 0.43 | 7500 | 0.68% | ||||

| 31204-1 | 0.18 | 0.20 | 35 | 30 | ≥600 | ≥380 | 0.43 | 7000 | 0.68% | ||||

| 5 heddle monolayer forming net | 30205 | 0.17 | 0.20 | 32 | 28.5 | ≥600 | ≥350 | 0.41 | 7100 | 0.60% | |||

| 31215 | 0.2 | 0.21 | 35 | 32 | ≥600 | ≥400 | 0.48 | 7000 | 0.60% | ||||

| 27255 | 0.2 | 0.25 | 30 | 22 | ≥600 | ≥400 | 0.50 | 8000 | 0.60% | ||||

| 8 heddle monolayer forming net | 25358 | 0.22 | 0.35 | 28 | 19.5 | ≥700 | ≥500 | 0.85 | 9000 | 0.65% | |||

| 25388 | 0.22 | 0.38 | 29.5 | 19 | ≥700 | ≥500 | 0.87 | 8500 | 0.65% | ||||

| 27358 | 0.22 | 0.35 | 29 | 20 | ≥700 | ≥500 | 0.85 | 8500 | 0.65% | ||||

| 27388 | 0.22 | 0.38 | 31.5 | 19 | ≥700 | ≥500 | 0.87 | 8000 | 0.65% | ||||

| 7 shed double layer forming fabric | 56177 | 0.17 | 0.17/0.20 | 60 | 48 | ≥800 | ≥600 | 0.635 | 5200 | 0.60% | |||

| 0.20(t66) | |||||||||||||

| 57177 | 0.17 | 0.17/0.22 | 65.7 | 49.6 | ≥800 | ≥600 | 0.635 | 4550 | 0.60% | ||||

| 0.22(t66) | |||||||||||||

| 8 shed double layer forming fabric | 56188 | 0.17 | 0.18/0.20 | 61.3 | 51.2 | ≥850 | ≥600 | 0.65 | 5700 | 0.60% | |||

| 0.20(t66) | |||||||||||||

| 60188 | 0.18 | 0.19/0.20 | 66 | 49 | ≥900 | ≥650 | 0.68 | 4750 | 0.60% | ||||

| 0.20(t66) | |||||||||||||

| 62188 | 0.15 | 0.16/0.19 | 70.5 | 50.5 | ≥900 | ≥650 | 0.6 | 6200 | 0.60% | ||||

| 0.19(t66) | |||||||||||||

| Weaving seriesAnd types | warp | weft(on the weft insertion/under) | warp | weft | Air permeability m³/m²h |

| 2 and a half forming net | 2B3316-380 | 0.28 | 37~38 | 37~38 | 6000 |

| 2B3316-445 | 0.25 | 39~40 | 33~34 | 7000 | |

| 2B4216-425 | 0.22 | 47~48 | 42~43 | 6800 | |

| 2B5616-350 | 0.17 | 62~63 | 43~44 | 5500 | |

| 2B5616-410 | 0.17 | 62~63 | 48~49 | 6500 | |

| 2B5608-375 | 0.17 | 62~63 | 61~62 | 6000 | |

| 2B6016-350 | 0.17 | 65~66 | 54~55 | 5000 | |

| 2B6016-410 | 0.17 | 65~66 | 49~50 | 6500 | |

| 3 and a half forming net | 3C4216-400 | 0.22/0.22 | 48~49 | 60~61 | 6300 |

| 3C5616-475 | 0.17/0.17 | 61~62 | 55~56 | 7500 | |

| 3C5620-315 | 0.15/0.20 | 66~67 | 58~59 | 5000 |

How to clean and maintain the polyester forming Mesh belt?

1.The main factors affecting the service life of forming mesh belt:

There are many factors that affect the life of the polyester forming fabric. It is not only affected by the forming method of the paper machine (such as Fourdrinier paper machine, net paper machine, overlapped paper machine, etc.) and paper machine technological conditions (such as dewatering element material, shape design). , Slurry type, ratio, filler type content, vacuum degree, net speed, net tension, net cleaning and fine fiber retention rate, etc.).

It is also related to the structure and type of the net itself (such as multi-wire nets, single-wire nets, single-layer nets, multi-layer nets, net thickness, etc.). Therefore, it is necessary to comprehensively consider various factors in actual production to achieve the purpose of extending the service life of the network.

1.We always use poly bag for the goods which ship by air, so that customer can save freight free.

2.Wooden case is the best for ocean shipment, because it can effective avoid the damage during shipping.

3.There also have some customer request us to use the carton to packing their goods.

4. As your required.

Q1: Can I book Storage Basket from you?

A1: Yes! You can! You are welcome to make a Storage Basket order to check our superior quality and service!

Q2: Do you have any After-Sale Service?

A2: Yes! We have professional After-sales services items and if you have any technical problem or question with the goods, welcome to contact our Technical Support Dept. or our sales directly, we must settle it ASAP.

Q3: Are you just trading co. or factory?

A3: We are professional manufacturer for Filtration, and We can support you with the most competitive pirce, unrivaled Quality and Services.

Q4: Where is your factory located? How can I visit you?

A4: Our factory is located in Anping County, Hebei Province of China. You can fly to Beijing City Airport directly, and we will pick you up. Welcome to visit our factory.

center

We’d love to hear from you!

Copyright © HEBEI REKING WIRE MESH CO.,LTD. All Rights Reserved

Technical Support: