- Tel : +86-0311-85236281

- E-mail : sales@wirecloths.com

Polyester mesh is made of polyester PET material, with strength several times that of woven dry blankets, canvas, nylon, and general plastic mesh. In addition, it also has the advantages of good breathability and high heat transfer efficiency, which can save energy for users. It is easy to install and use and is widely used in non-woven fabric manufacturing, papermaking, environmental filtration, food, printing, coal washing and other industries.

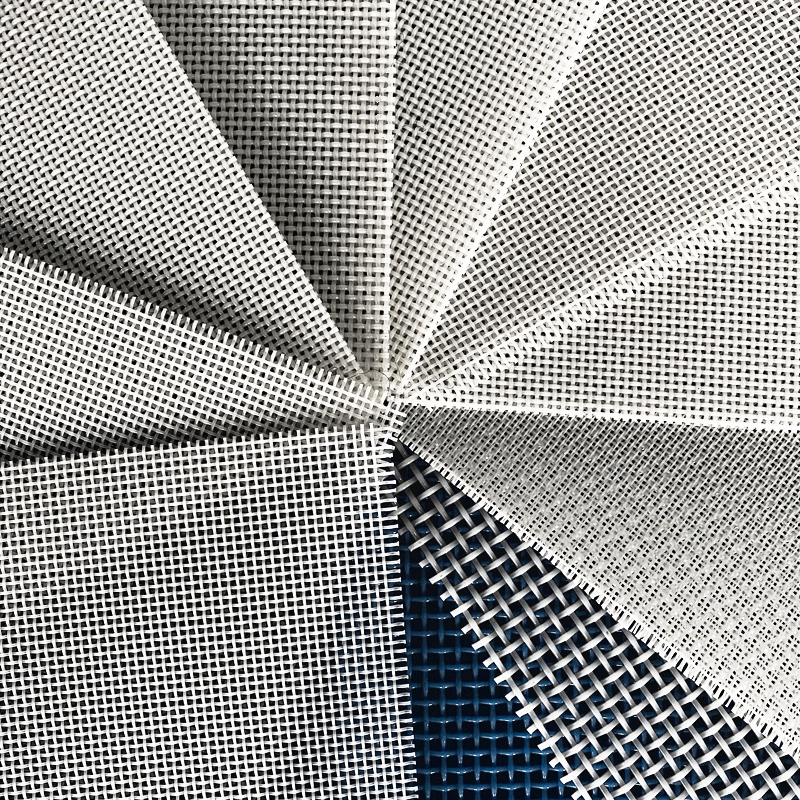

According to different weaving methods and usage scenarios, polyester mesh can generally be divided into types such as non-woven mesh belts, polyester spiral mesh, square hole flat woven mesh, herringbone sludge dewatering mesh, spiral pressure filter mesh, paper forming mesh, anti-static mesh, desulfurization mesh, etc.

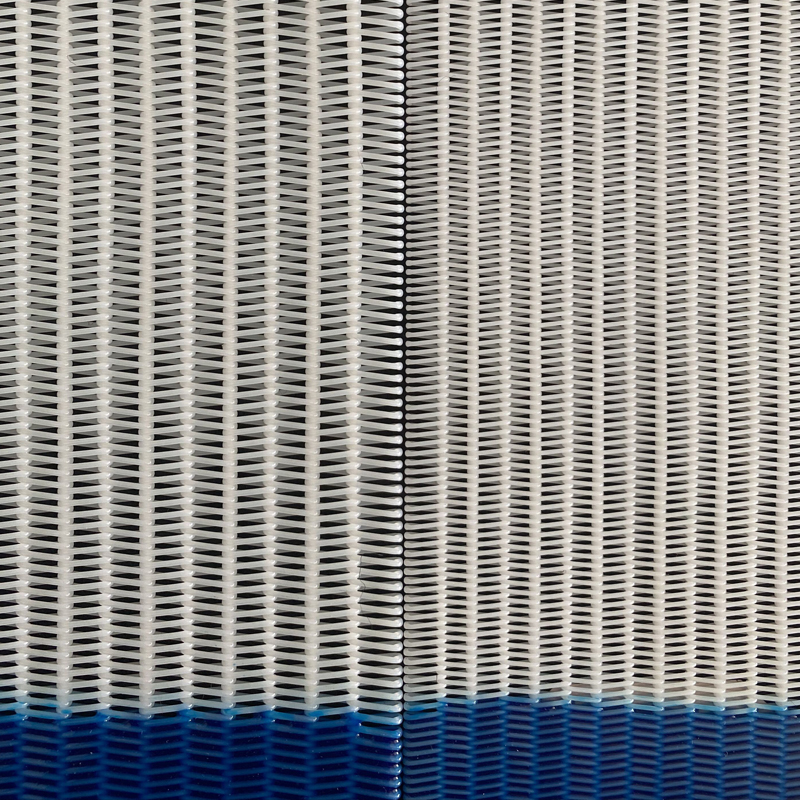

Polyester spiral mesh: It has the advantages of high breathability, flat mesh surface, easy disassembly and connection, good strength, and long service life. The special material spiral dry net also has characteristics such as high temperature resistance, high wear resistance, and aging resistance. Widely used in the melt blown non-woven fabric, papermaking, coal mining, food, medicine, printing and dyeing, and rubber product industries, suitable for horizontal belt vacuum pulp washing machine bottom mesh, and can also be used as a conveyor belt and composite machine matching mesh belt.

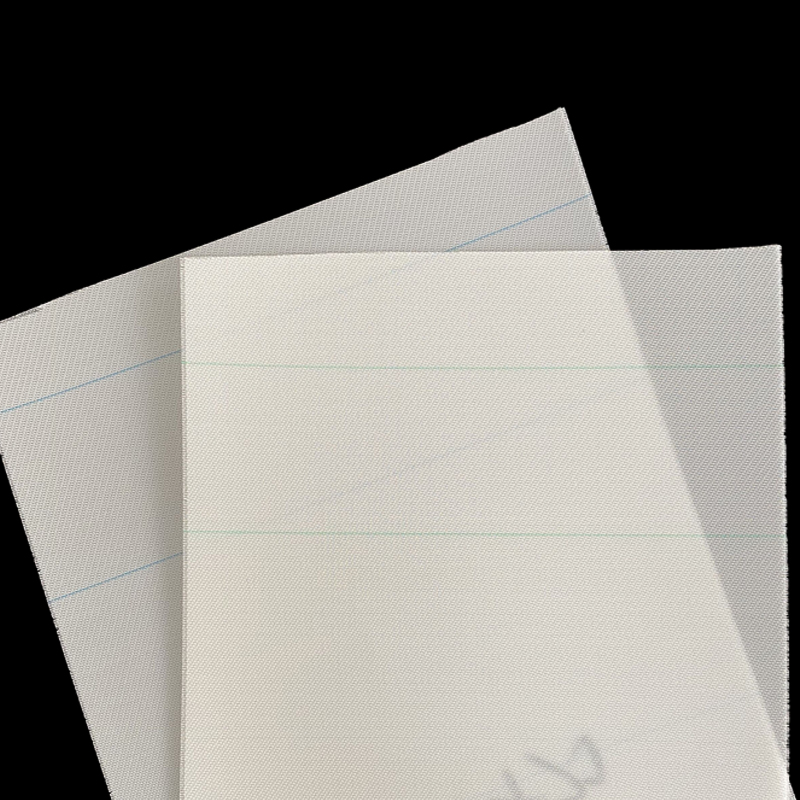

Paper forming net: It is an important equipment on a paper machine, which is a device for forming and dehydrating paper sheets. It dehydrates the pulp suspension from the headbox and runs the paper web to subsequent sections. Formed nets have multiple models and classification methods, generally classified by the number of layers and bundles. For example, it can be divided into four types of single-layer network, five types of single-layer network, eight types of single-layer network, eight types of double-layer network, sixteen types of two-layer and half network, twenty-four types of three-layer network, etc.

Square hole flat woven mesh: It has the characteristics of being non-toxic, odorless, with a smooth and anti stick surface, corrosion resistance, good flexibility, wear resistance, high tensile strength, and easy cleaning. Mainly used in non-woven fabric manufacturing, artificial board factory paving machines, fruit and vegetable conveying and drying, sludge dewatering machines, material screening, environmental protection and other industries. The general classification method is based on density and the number of mesh holes, with a unit of "mesh". The 2-40 mesh corresponds to different models, such as 09502, 07802, 06803, 08502, etc. The specific resolution method is to measure the number of mesh holes within one inch (2.54CM) parallel to a ruler, which is the mesh count.

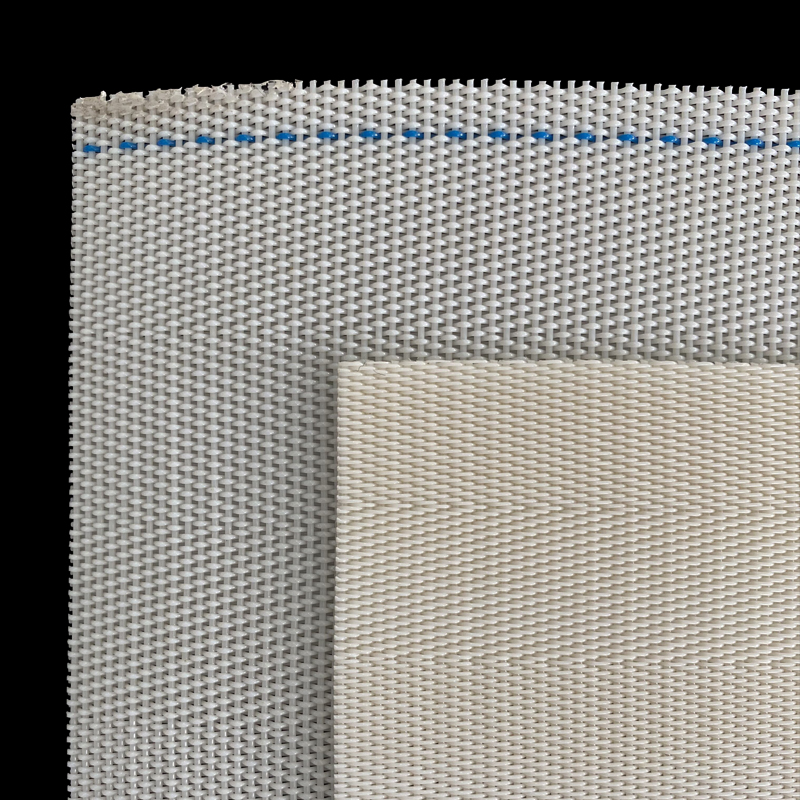

Herring-shaped sludge dewatering net: mainly used for belt filter presses, rubber belt vacuum filters, and horizontal vacuum belt filters. Suitable for pressing and filtering municipal household sludge, sludge from various industries and enterprises, pulp pressing in paper mills, concentrated fruit juice pressing, and other special industries. Features: Due to the herringbone design of the mesh belt, the sludge and mesh belt peel off quickly, are not easy to stick to, are easy to clean, and connect quickly and conveniently.

Spiral pressure filter mesh: Spiral pressure filter mesh is a type of filter that adds filler wire into a spiral ring to reduce air permeability and material loss on the mesh surface. It is mainly used for pressing and filtering belts in belt dehydrators, as well as in industries such as papermaking, printing and dyeing, food, chemical, alcohol, vinegar, coal washing, mining, paper pulp washing, pharmaceuticals, sludge dewatering, ceramics, and sludge dewatering for solid-liquid separation.

Anti static power grid: Equipment using polyester mesh will generate static electricity during high-speed operation due to friction. Conductive fiber filaments can be threaded inside the polyester mesh to release static electricity, thus playing an anti-static role. Mainly used in non-woven fabric manufacturing, environmental protection, high-density board production, rubber, chemical fiber, dry papermaking, fiberboard continuous press mesh belt, continuous pre press mesh belt and materials that require conductivity and anti-static industries.

Desulfurization net: The vacuum filter net (desulfurization net) belt has the characteristics of stable operation, less wrinkling, high filtration accuracy, and good cake stripping. It is mainly used in conjunction with rubber belt vacuum filters, horizontal belt vacuum filters, drum vacuum filters, and vertical filter presses. Suitable for wet desulfurization of power plants, tailings, metallurgy, mining, chemical, coal chemical, papermaking, food, pharmaceuticals, and environmental protection industries for solid-liquid separation.

Our company can provide all the above products. Please feel free to contact us

Copyright © HEBEI REKING WIRE MESH CO.,LTD. All Rights Reserved

Technical Support: