- Tel : +86-0311-85236281

- E-mail : sales@wirecloths.com

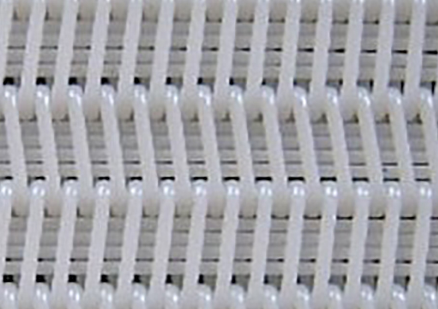

Extraction Press Filter Fabric Belt cleaning operation procedure

purpose

Standardize the extraction filter cleaning operation program, carry out equipment maintenance, and ensure continuous and normal production.

Scope of application

This procedure is applicable to the cleaning operation of the filter cloth in the extraction section.

The extraction staff is responsible for the cleaning of the filter cloth to ensure that the filter cloth cleaning is effective and thorough, and the quality and operation of the filter cloth are recorded.

The section length is responsible for testing the filter cloth cleaning results, monitoring the cleaning process and results, and polyester filter cloth.

Vacuum Filter Belt cleaning

Washing liquid preparation

Add water to the four washing tanks to three molecules of the volume.

Add concentrated acid (or concentrated alkali) to the barrel and mix the concentration of the cleaning solution to the left and right.

Steam is introduced, the alkali is heated to 75 ° C ± 5 ° C, the acid is heated to 65 ° C ± 5 ° C, the hot water is heated to above 80 ° C, the heating temperature is reached, and the steam is turned off.

Washed

Put the filter cloth in a silk washer and rinse it with water.

Pickling

After the washing is completed, the filter cloth is drained and drained.

Immerse the filter cloth in hot acid solution and soak for 1 hour.

Copyright © HEBEI REKING WIRE MESH CO.,LTD. All Rights Reserved

Technical Support: