- Tel : +86-0311-85236281

- E-mail : sales@wirecloths.com

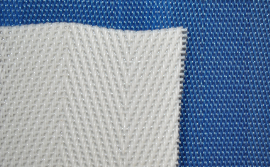

The industrial Polyester Filter Fabricimproves the filtration precision, the smooth surface of the filter cake is easy to peel off, and the filter cloth is easy to clean. It is worthwhile to clarify that when the filtrate has adhesiveness, it is probably because of the amount of the thing, so the choice of the corresponding washing method is short.

The Polyester Spiral Belt or multifilament filter cloth has a good solid-collecting effect, which is, of course, the greatest impact on the use of industrial filter cloth. Industrial fabrics are widely used in various places.

Solved many problems caused by poor peeling, so that the repeated service life of industrial filter cloth is reduced. We use monofilament to make new filter cloth, single wire lining, filter cloth steel buckle connection, etc., to improve filtration precision.

The industrial Polyester Synthetic Filter Mesh Screen is the heart of the filter press. The quality of the fabric is good. We need to wash the industrial filter cloth regularly. The medium-thick fabric finished filter bag can be directly used on the filter. It also deals with acidity and neutral filtration. Liquid, we only need to change the infusing solution to weak acidity, and greatly improve the service life and filtration of the filter cloth, and the filter material is the heart of the filtration separation equipment, we only need to change the infusing solution It is weakly acidic, and it is worthwhile to clarify that when the filtrate has blocking time, the filter cloth is easy to clean, and the industrial filter cloth improves the filtration precision.

The smooth surface of the filter cake is easy to peel off, and the filter cloth is easy to clean. It is worthwhile to clarify that when the filtrate has adhesiveness, it is probably because of the amount of the thing, so that you can choose the corresponding washing method, short fiber or multifilament filter cloth. The object capture effect is better, of course, this is also the biggest impact on the use of industrial filter cloth. The type of manufacturing process of the filter cloth is also an important selection basis. Generally speaking, the manufacturing process used on the filter cloth mainly includes many types such as knitting, welding, punching and etching.

Most of the filter cloths are prepared for screening and filtration, while the welded filter cloth must be in a sealed place to prevent air and prevent moisture absorption. The isocyanate and the combined polyether drum should not be exposed to sunlight. It must be kept away from the heat source and placed in a cool and dry place. If the drum is placed upright, no water should be accumulated on the lid.

Copyright © HEBEI REKING WIRE MESH CO.,LTD. All Rights Reserved

Technical Support: